Introduction: Why Turbo Torches Are Used in Industrial Heating

In many industrial heating tasks, speed and heat concentration are critical. Traditional welding torches can deliver sufficient heat, but they are not always optimized for rapid temperature rise or localized heating.

Turbo torches are designed to address these requirements by producing a high-intensity, swirling flame that concentrates heat output. This makes them especially suitable for industrial maintenance, brazing, soldering, and repair operations where efficiency directly affects productivity.

What Makes a Turbo Torch Different from Standard Torches

Turbo torches differ from conventional gas torches primarily in flame generation. Instead of a straight flame, a turbo torch creates a rotating or vortex-style flame that increases heat transfer efficiency.

This flame structure allows more heat energy to be delivered to the target area in a shorter time, reducing overall heating duration and fuel consumption in repetitive tasks.

How Turbo Torch Design Improves Heating Efficiency

Swirling Flame and Heat Concentration

The core feature of a turbo torch is its swirling flame design. By introducing rotational motion to the gas flow, the flame wraps around the workpiece more effectively, improving surface contact and heat absorption.

This design enables faster heating compared to linear flame torches, particularly on pipes, fittings, and metal joints.

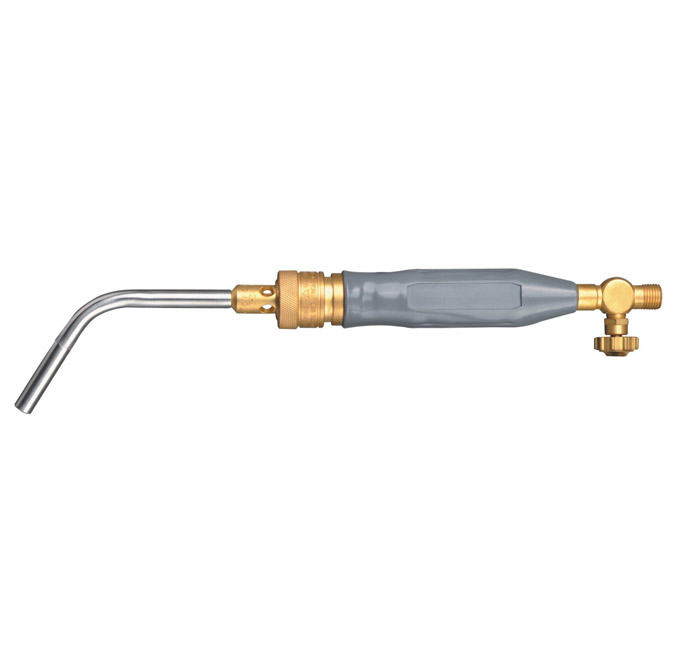

Controlled Gas Flow and Stability

Turbo torches are engineered to maintain stable gas flow even under high output. Consistent flame behavior is essential for preventing uneven heating and ensuring predictable results in industrial applications.

Stable output also improves operator control, reducing the risk of overheating or material damage.

Materials and Construction for Industrial Durability

Industrial turbo torches are typically manufactured using brass, stainless steel, and heat-resistant grip materials. These components are selected to withstand high temperatures and repeated thermal cycling.

Robust construction ensures that the torch maintains structural integrity during prolonged use, making it suitable for professional environments where reliability is essential.

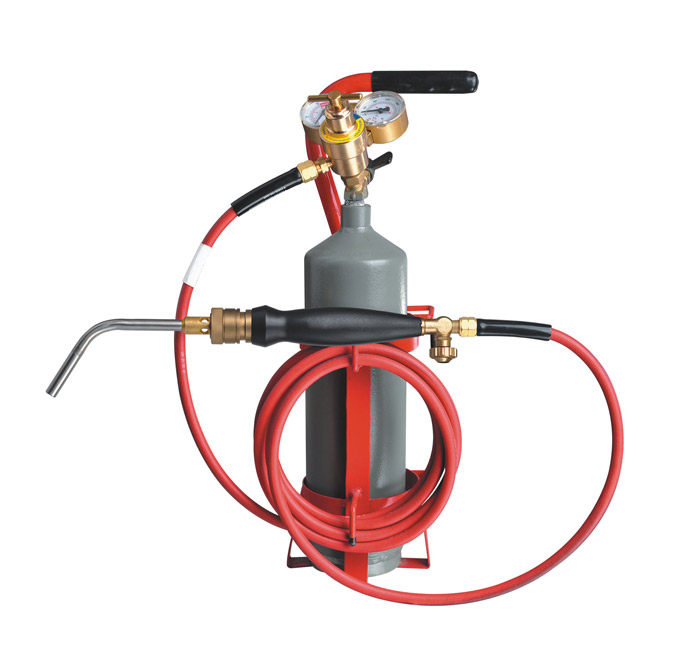

Safety Considerations in Turbo Torch Applications

High-output heating tools require careful safety design. Turbo torches are designed with secure gas connections, reliable valves, and compatibility with standard safety accessories.

These features help reduce gas leakage risks and support safe operation in workshops, job sites, and maintenance environments where multiple users may operate the equipment.

Common Industrial Applications of Turbo Torches

Turbo torches are widely used in plumbing and HVAC installation, industrial maintenance, metal fabrication repair, refrigeration service, and equipment assembly.

Their ability to deliver fast, concentrated heat makes them particularly effective for brazing and soldering tasks where speed and precision are required.

What B2B Buyers Should Consider When Sourcing Turbo Torches

For distributors and industrial buyers, evaluating turbo torches involves assessing heating efficiency, material quality, flame stability, and compatibility with existing gas systems.

Reliable turbo torches help reduce job completion time, improve workflow efficiency, and support consistent performance across multiple work sites.

Conclusion: Turbo Torches as High-Efficiency Heating Tools

Turbo torches are purpose-built for applications that demand rapid and concentrated heat delivery. Through advanced flame design and durable construction, they provide industrial users with an efficient solution for heating-intensive tasks.

Understanding turbo torch technology helps B2B buyers select tools that align with productivity goals and long-term operational reliability.