Introduction: Heating Challenges in On-Site Industrial Work

Industrial maintenance and repair tasks are often performed in environments where access to fixed gas systems or electrical heating equipment is limited. On-site work requires tools that can deliver sufficient heat quickly while remaining easy to transport and set up.

Portable turbo torch systems are designed to meet these conditions by integrating the gas source, pressure control, hose, and torch into a compact and mobile solution.

What Is a Portable Turbo Torch System

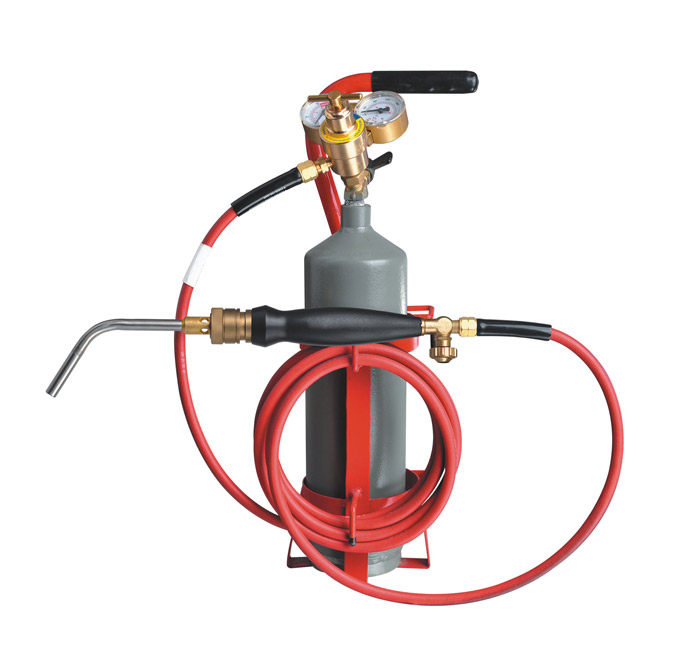

A portable turbo torch system typically consists of a refillable gas cylinder, pressure regulator with gauge, reinforced gas hose, and a turbo torch designed for high-intensity heating. Unlike standalone torches, this system approach ensures controlled gas delivery and stable flame output in mobile applications.

By combining these components into a single setup, industrial users can perform heating tasks without relying on external infrastructure.

How Turbo Torch Systems Improve On-Site Efficiency

Fast Heat-Up for Time-Sensitive Tasks

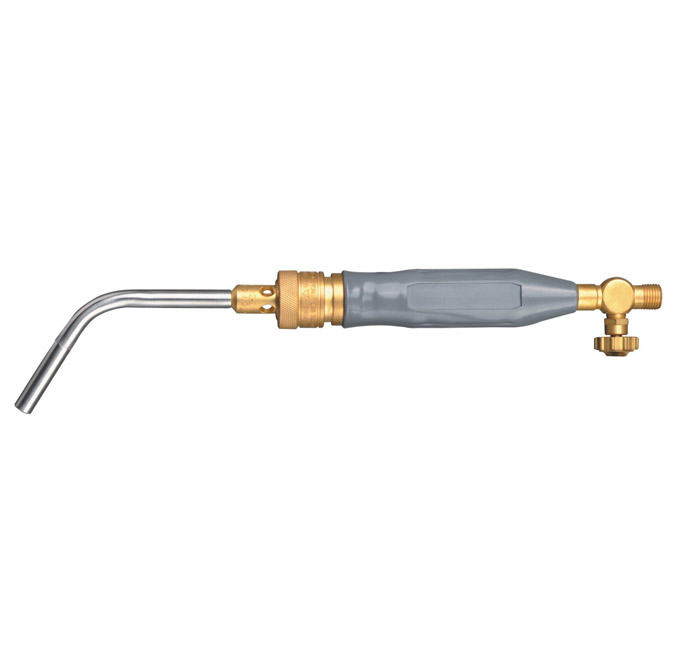

Turbo torch technology generates a swirling, high-intensity flame that concentrates heat onto the target area. This allows joints, fittings, and metal surfaces to reach working temperature quickly, reducing overall task duration.

In maintenance environments where downtime is costly, faster heating directly improves operational efficiency.

Mobility and Flexible Deployment

Portable systems allow technicians to move easily between work locations. Whether used in factories, construction sites, or field maintenance, the integrated design supports flexible deployment without complex setup procedures.

This mobility is especially valuable for repair teams handling multiple jobs within a single shift.

Safety and Control in Portable Heating Applications

Despite their high output, turbo torch systems are designed with safety in mind. Pressure regulators provide controlled gas flow, while secure hose connections and shut-off valves help minimize leakage risks.

Stable flame behavior and predictable heat output allow operators to work with greater confidence, even in confined or variable environments.

Materials and Construction for Industrial Use

Portable turbo torch systems are built using durable materials such as steel cylinders, brass fittings, and heat-resistant grip components. These materials are selected to withstand repeated heating cycles, transport stress, and exposure to industrial environments.

Robust construction supports long service life and reduces maintenance requirements for professional users.

Common Industrial Applications of Portable Turbo Torch Systems

These systems are widely used in industrial maintenance, plumbing and HVAC service, equipment repair, metal assembly, and infrastructure work. Typical tasks include brazing, soldering, loosening seized fasteners, and localized heating.

The combination of speed, portability, and control makes turbo torch systems a practical choice for a wide range of on-site applications.

What B2B Buyers Should Consider When Sourcing Turbo Torch Systems

For distributors and industrial buyers, evaluating portable turbo torch systems involves assessing heating performance, regulator reliability, component quality, and system safety.

A well-designed system helps reduce setup time, improve workflow efficiency, and support consistent performance across multiple job sites.

Conclusion: Portable Turbo Torch Systems as On-Site Heating Solutions

Portable turbo torch systems provide industrial users with a reliable and efficient heating solution for on-site maintenance and repair work. By combining fast heat output with mobility and safety features, these systems support productivity in environments where traditional heating methods are impractical.

Understanding their design and application helps B2B buyers select equipment aligned with real-world operational needs.